2025 Primary Packaging Trends

When it comes to creating primary packaging that stands out, the options are plentiful. So plentiful, in fact, that you might find yourself overwhelmed to make a decision to maximize both value and connection with your customers. We tapped our resident packaging expert, Jing Santos, to discover what packaging trends we’ve seen growing in the last few years, and what we can expect to see more of in 2025.

A Focus on Impact We know that now more than ever, our customers expect products that not only deliver results, but make a positive impact on the world or the communities they care about most. There are multiple pathways to achieve this through packaging, and most focus on materials and forms that can be broken down or utilized again and again. Here are some things to consider:

- Sustainability: While broad, you can think of a sustainable mindset as doing everything you can—from formula to packaging to shipping—to reduce your impact. This is more of an overarching brand theme than something tactical to implement.

- Design for Recyclability: While many packages claim recyclability, it’s important to consider ease for your customer. If impact is what you’re after, ensure that your pieces are easily recyclable through at-home programs.

- Renewable & Biodegradable Materials: These are materials that minimize impact through responsible sourcing and disposal—meaning they won’t deplete in nature, and they won’t stick around forever in landfills.

- Post-Consumer Recycled Materials: These are materials that take advantage of previous recycling programs to create something new, innovating to reduce the amount of true waste.

- Mono-Materials: Made from one true component, like glass or aluminum, these materials are often easier to recycle due to their simplicity.

- Refillable Packaging: By encouraging your customer to reuse your most elaborate primary packages, you can help them cut back on waste and repurchasing when unnecessary.

- Bio Resins: Made from biological sources like vegetable oil (instead of petroleum), these plastics decrease carbon footprint while providing the same effect as traditional plastics.

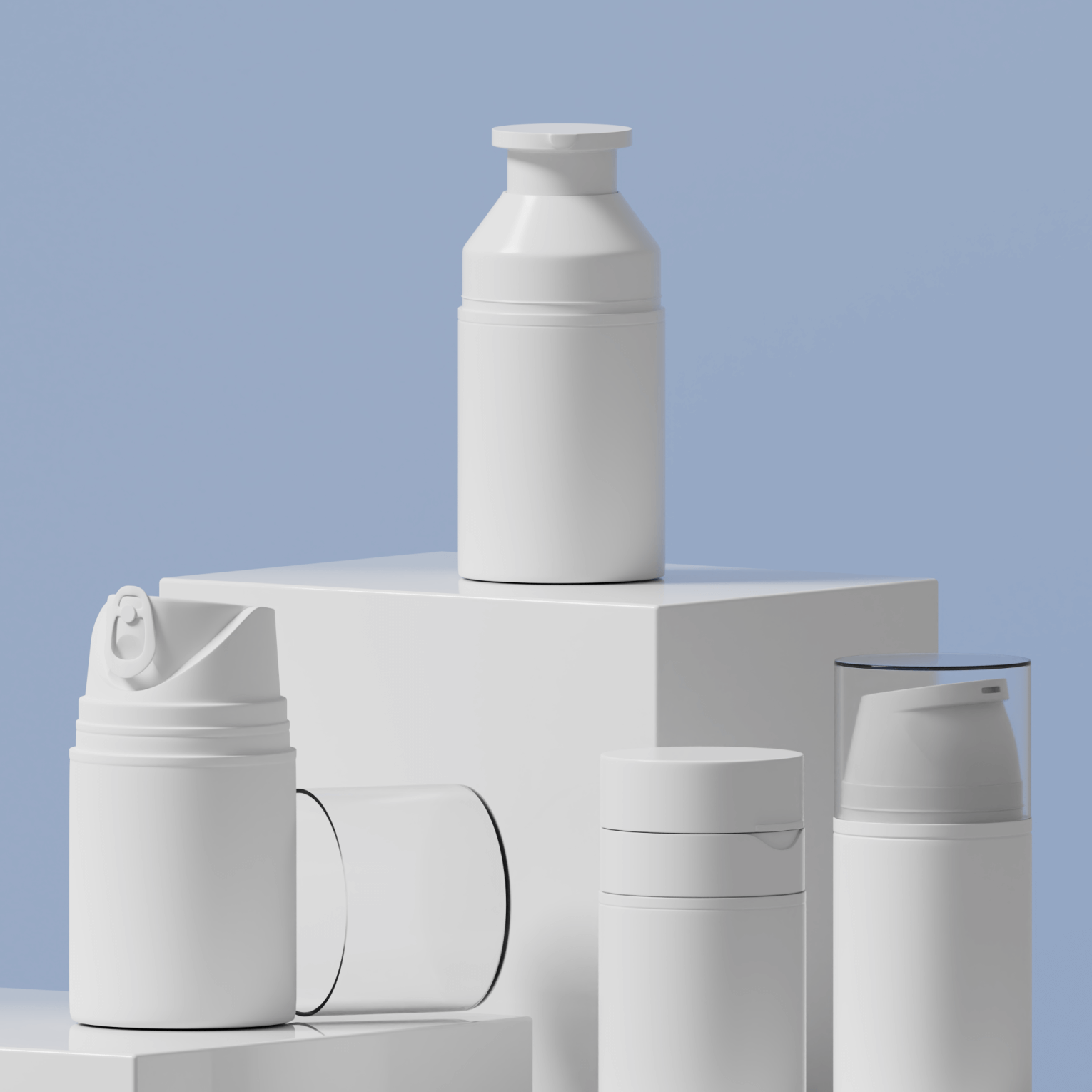

Design for Efficacy In similar importance for today’s customer is the efficacy of the products they purchase—and that goes beyond formula. They want to ensure the product they’re getting isn’t backed by false claims, but instead is crafted to actually deliver what they need it to. And they won’t be fooled by gimmicks or empty marketing tactics. Here’s what they’re looking for:

- Airless Packaging: Oftentimes, formulas become less effective when exposed to oxygen, especially over long periods of time. These airtight bottles can help extend the efficacy of your product while it’s on the shelf.

- Glass & Aluminium Packaging: Customers are hyper aware of microplastics and the effect of plastic on the environment, and glass and aluminum can help assure them that their product is clean when they put it on their skin—and they can recycle it when they’re done. Win-win.

- Opaque Packaging: Whether through choice of material or coloring, opaque packaging can also help extend the efficacy of your product by minimizing its exposure to light, which can diminish the power of certain ingredients.

By working with a full-service product partner like The DPS, you can ensure your formula and your packaging are compatible, giving you an extremely efficient pathway to launch success. To get started on your 2025 projects, reach out to schedule a complimentary consultation today.